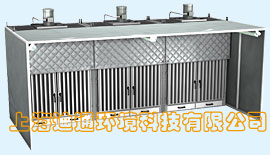

Grinding workshop

MCB- Grinding workshopApplied range

It is suitable for treating the flue gas and dust produced by grinding, grinding, welding, polishing and powder spraying.

Operating principle

The MCB welding and grinding workshop generates a lateral airflow on one side of the operating area. The lateral ventilation is used to drive pollutants before they enter the operator's breathing belt. The pollutants are then filtered by an internal filter to ensure indoor air quality.

Product description

1. The MCB welding and polishing workshop is designed to capture dust and dust while providing adequate working space for workers.

2. Modular design is adopted, which can be assembled flexibly to meet various needs.

3. MCB built-in purifier, using a closed pulse ash cleaning system, compared with similar products to reduce 50% of the noise level.Moreover, this kind of purifier does not need to install any pipe, saving installation time and installation cost.

4. The MCB purifier is equipped with a nanofiber filter cartridge, which ensures the filtration efficiency and achieves greater ventilation volume and less ventilation resistance.

Specification

| Parameter Name | Ventilation Quantity (m3/h) | Dimension (mm) | ||

| Length | Wide | High | ||

| MCB-03 | 7650 | 915 | 1065 | 2480 |

| MCB-06-01-S | 15300 | 2030 | 1065 | 2685 |

| MCB-09-10-S | 22950 | 2950 | 1065 | 2710 |